The City had been treating wastewater at the site since 1940. Existing facilities included preliminary treatment, primary clarification, a carbonaceous trickling filter, intermediate clarification, a nitrification trickling filter, final clarification, anaerobic digestion, and liquid sludge storage.

Flow records and observations by City staff indicated that the collection system conveyed much more flow than what the treatment plant could hydraulically pass or effectively treat during periods of high rainfall. These frequent wet-weather flow events resulted in untreated wastewater being bypassed to the East Nishnabotna River.

These hydraulic challenges were compounded with new regulatory requirements mandating that disinfection be implemented. The City reviewed alternatives for new treatment facilities at potential treatment sites, but the high cost caused the City to reduce the scope of the project to adding new flow equalization, raw wastewater pumping, and disinfection.

We were selected to design these new additions to the existing plant that were to be constructed next to the existing treatment facilities. One of the benefits to staying on the existing site was that the administration, maintenance, and lab building, as well as two tanks could continue to be used after renovation. Two smaller buildings were kept and used for additional storage space.

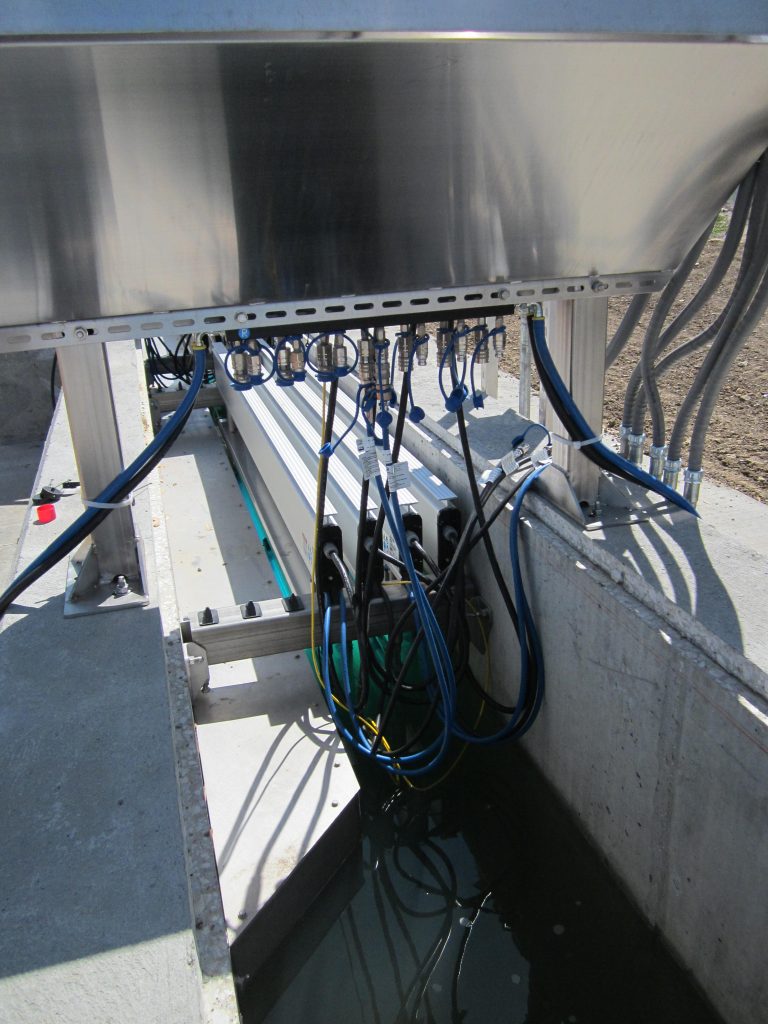

The project included a new 7 MG earthen flow equalization basin, new interceptor sewers with larger capacity to eliminate sanitary sewer backups on the smaller trunk sewer side, new preliminary treatment building with automated screening and grit removal, screenings and grit washers, raw wastewater sampling, flow metering, and raw pump station in a self-cleaning trench-style wet well. In addition, we designed a new blower building to house new positive displacement blowers for the Sequencing Batch Reactor (SBR) secondary treatment process and aerobic sludge holding tanks, main electrical room, and offseason storage for ultraviolet (UV) modules; new outdoor emergency power generator; four new, continuous inflow SBRs with fine-bubble membrane diffusers, automatic real-time measurement of dissolved oxygen and liquid level in the reactors. A new UV disinfection system was added and the existing final clarifier and sludge storage tank were modified to two aerobic sludge holding tanks. Finally, we updated the reed bed sludge digestion and dewatering facility, renovated the laboratory, and modified the 6th Street pump station.

Awards Won:

• ACEC IA Engineering Excellence Honor Award